Closed projects material industry

Closed projects out of the scope of construction material.

References in material industry

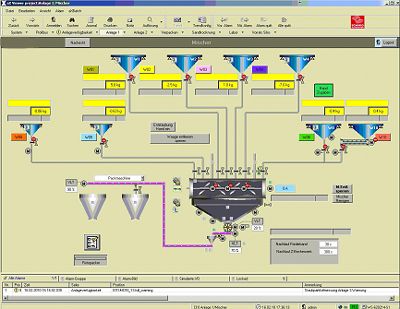

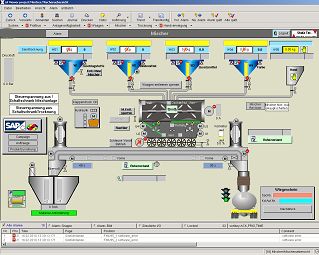

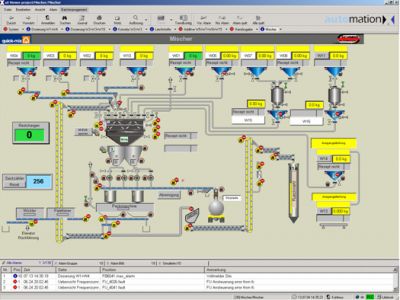

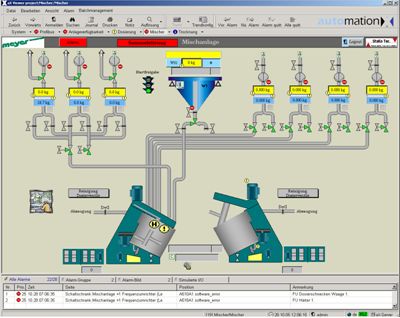

Control and visualisation of a dry plaster blending device

Place of delivery: Germany

Technical data:

- dry plaster blending device with 2 lines

- S88-2 batch management system

- contractor Schmid Automation Switzerland

- connection to SAP order management system

- ET200M in and output components

- Siwarex weighing system

- connection to Bluhm DSS Manager

- connection to Ventilex drying

StaKo Tec. service package:

- service on site

- balance maintenance service

- remote maintenance

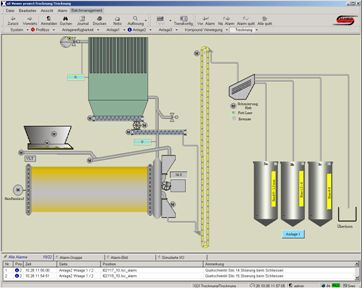

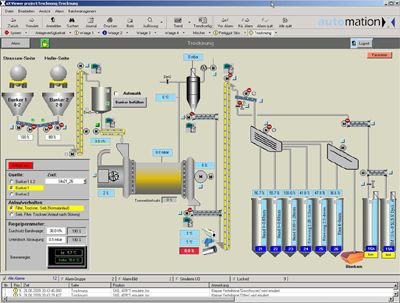

Control and visualisation of a sand drying facility with humidity control system

Place of delivery: Germany

Technical data:

- 3 blending lines, 18 scales, sand drying with humidity control system

- 1800 physical in and outputs

- batch management system according to S88-2

- Oracle datenbank system for the recording of processing data

- integration of all automatical and manual production steps

- optimisation sand drying with weather data adjustment

- recording energy consumption processing parameters

- works control by means of network monitoring systems

- belt weigher system

StaKo Tec. service package:

- base study, engineering

- implementaion, plant extension, software adjustment on site

- training

- remote maintenance

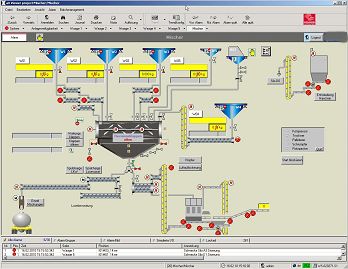

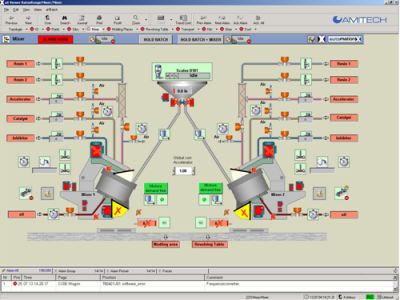

Control and visualisation of a dry plaster blending facility 3

Place of delivery: Germany

Technical data:

- dry plaster blending facility

- S88-2 batch management system

- contractor Schmid Automation Switzerland

- connection to SAP order system

- ET200M in and output components

- Siwarex weighing system

- connection to Bluhm DSS Manager

StaKo Tec. service package:

- service on site

- scales service

- remote maintenance

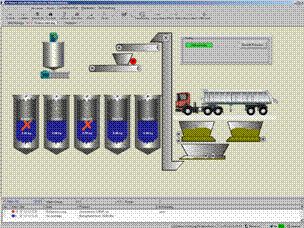

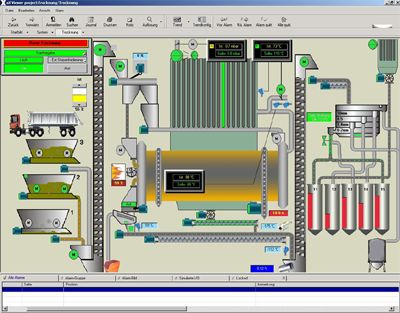

Control and visualisation of a blending device with vehicle administration

Place of delivery: Germany

Technical data:

- 1 mixing line, 5 scales, sand drying

- 450 physical in and outputs

- MySQL databank with webfrontend data evaluation

- recording of all automatical and manual production steps

StaKo Tec. service package:

- base study, re-engineering control technology and batch steering

- preparation of control and visualisation of the batch system according to S88 and vehicle administration

- data recording and analysis

- electronical engineering

- construction of a switch cabinet

- implementation

- training

- remote maintenance

Control and visualisation of a calibratable mixing device

Place of delivery: Germany

Technical data:

- calibratable mixing device

- connection to SAP order management via RFC

- 1 mixing line, 5 scales, sand drying

- 450 physical in and outputs

- MSSQL databank with mit webfrontend data analysis

- recording of all automatic and manual production steps

StaKo Tec. service package:

- reengineering control technology and batch control

- preparation of control and visualisation, batch system according to S88 + vehicle management

- data recording and evaluation

- electric engineering

- exchange Siemens S5 against Beckhoff E/A components

- implementation

- training

- remote maintenance

Control and visualisation of an industrial concrete plant

Place of delivery: Germany

Technical data:

- industrial concrete plant with 1 mixing line, 2 scales, 5 time dosing systems, water dosing system

- 250 physical in and outputs

- integration of all automatic and manual production steps

StaKo Tec. service package:

- base study, reengineering control technology and batch control

- preparation of control and visualisation, batch system.

- data recording and evaluation on customer's demand with Access data bank

- electric engineering

- construction of switch cabinet

- implementation

- training

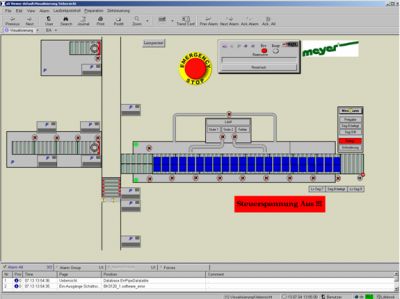

Control and visualisation of an automatic pipe conveyor

Place of delivery: Germany

Technical data:

- automatic pipe conveyor with temper tunnel for the conveying and tempering of polymer concrete pipes

- approx.150 physical in and outputs

- integration of all automatical and manual production steps

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording with MySQL databank system and evaluation via web-frontend

- electric engineering

- construction of switch cabinet

- implementation

- training

Control and visualisation of a recirculated sludge grinding device

Place of delivery: Germany

Technical data:

- grinding device for recirculated sludge for the production of porous concrete

- 350 physical in and outputs

- 6KV engine / starter steering

- differential and conveyor belt scales

- network monitoring

- recording of all automatic and manual production steps

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording and evaluation

- electric engineering

- construction of switch cabinet

- implementation

- training

Optimisation of scales, mixing and volumen dosing lines

Place of delivery: Germany

Technical data:

- 1 mixing line, 14 scales, volume dosing line

- 1800 physical in and outputs

- batch management system according to S88-2

- Oracle datenbank system for the recording of processing data

- integration of all automatic and manual production steps

StaKo Tec. service package:

- base study

- implementation and extension of the plant

- software adaption on site

- training

- 24 h support 365 days per year

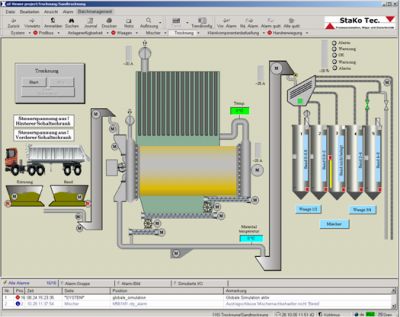

Control of a sand drying facility with humidity control system

Place of delivery: Germany

Technical data:

- 1800 physical in and outputs

- batch management system according to S88-2

- Oracle datenbank system for the recording of processing data

- integration of all automatic and manual production steps

StaKo Tec. service package:

- base study, engineering

- implementation and extension of the plant

- software adaption on site

- training

- 24h support 365 days per year

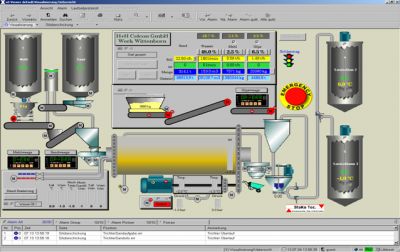

Mixing plant for the production of polymer concrete with pipe transport steering

Place of delivery: Germany

Technical data:

- mixing plant for the production of polymer contrete with pipe tranport steering

- 1200 physical in and outputs

- hot-standby redundance

- Oracle databank server for the recording of processing data

- integration of all automatical and manual production steps

StaKo Tec. service package:

- base study, engineering control technology

- adaption of control and visualisation

- data recording and evaluation

- electric engineering

- implementation

- training

- 24h support 365 Tage per year

Control and visualisation of a sand drying facility

Place of delivery: Germany

Technical data:

- 1 mixing line, 5 scales, sand drying

- 450 physical in and outputs

- MySQL databank with webfrontend data evaluation

- recording of all automatic and manual production steps

StaKo Tec. service package:

- base study, reengineering control technology and batch steering

- preparation of control and visualisation

- batch system according to S88 + vehicle management

- data recording and evaluation

- electric engineering

- construction of switch cabinet

- implementation

- training

Control and visualisation of a liquid dosing device

Place of delivery: Germany

Technical data:

- 2 mixing lines, 1 scale, 5 Coriolis liquid dosing systems

- 450 physical in and outputs

- additive drying

- management of production space and allocated systems (tempering tunnel)

- MySQL databank with webfrontend for data evaluation

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation, batch system according to S88

- data recording and evaluation

- electric engineering

- construction of swith cabinet

- implementation

- training

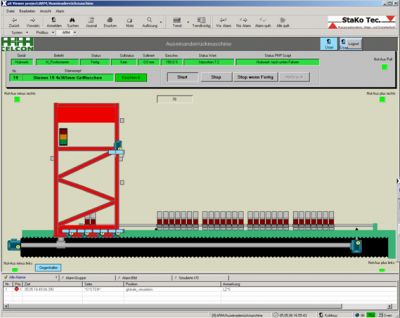

Control and visualisation of a separation device for porous concrete stones

Place of delivery: Germany

Technical data:

- separation device for porous concrete stones

- compound management for stone selection

- very exact positioning via Profibus servo converter

- automatic position calculation

- data link via über Profibus / Modbus / Ethernet

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording and evaluation

- electric engineering

- construction switch cabinet

- implementation

- training

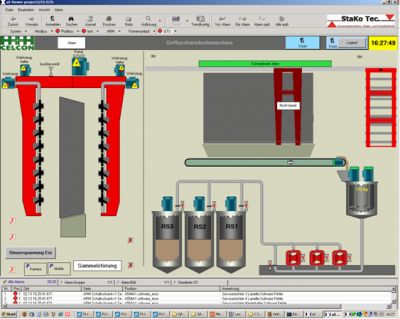

Control and visualisation of a grip hole cutting device for porous concrete stones

Place of delivery: Germany

Technical data:

- grip hole cutting device for porous concrete stones

- connection to Oracle databank for control parameters

- very exact positioning via Profibus servo converter

- automatic position calculation

- data link via Profibus / Modbus / Ethernet

- data exchange with AEG Modicon SPS via Modbus

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording and evaluation

- electric engineering

- construction of switch cabinet

- implementation

- training

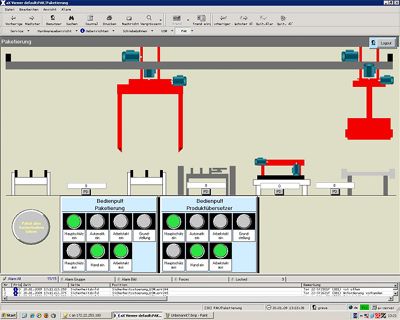

Extension of a porous concrete facility

Place of delivery: Germany

Technical data:

- control server with approx. 3500 in and outputs, 4 clients and 5 SPS control systems

- control of a porous concrete transport system

- connection to Rekers control systems

- connection to external packaging systems

- stock management system

- labeling system

- monitoring via network cameras

StaKo Tec. service package:

- concept elaboration with company Rekers

- connection to external control systems

- preparation of a driver SPS communication

- electric engineering network

- adaption of various S7 programs of exernal producers

- implementation

- training

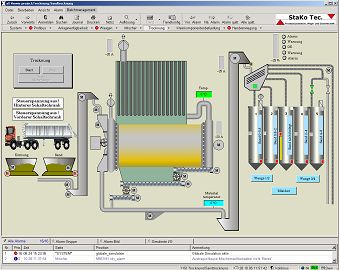

Control and visualisation of a sand drying facility

Place of delivery: Germany

Technical data:

- sand drying

- humidity control sensor system

- burner and waste air control as well as function control

- in and outputs routed via S5 135U / IM308-C

- connection to existing mixer control system

- trend recording of all processing parameters

StaKo Tec. service package:

- reengineering of existing control technology

- preparation of control and visualisation

- data recording and evaluation

- electric engineering

- projection of old S5 Komponenten ( IM308-C )

- connection to old Modicon E/A components

- implementation / adjustment

- training

- remote maintenance

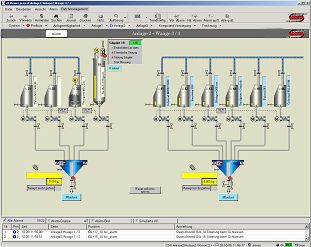

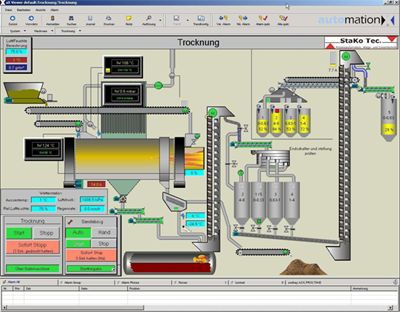

Control and visualisation of a dry plaster blending device 2

Place of delivery: Germany

Technical data:

- dry plaster blending device

- S88-2 batch management system

- contractor Schmid Automation Switzerland

- connection to SAP order system

- ET200M in and output components

- Siwarex weighing system

- connection to Bluhm DSS Manager

StaKo Tec. service package:

- implementation of optimised drying

- adjustment drying sensor system

- preparation of software for loop circuits

- electric engineering drying process

- implementation

- training

- remote maintenance

Control and visualisation for a sand drying facility 2

Place of delivery: Germany

Technical data:

- sand drying

- humidity control system

- optimisation of burner and function control

- Ethercat network in and outputs

- connection to weather station and data recording

- trend recording of all analog control points

StaKo Tec. service package:

- reengineering control technology

- preparation of control and visualisation

- data recording and evaluation

- electronic engineering

- construction switch cabinet

- implementation

- training

- remote maintenance

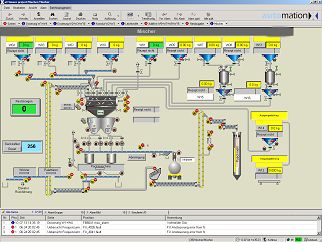

Control and visualisation of a blending facility with sand drying

Place of delivery: Germany

Technical data:

- 1 blending line, 14 scales, volume dosing line

- 1800 physical in and outputs

- batch management system according to S88-2

- Oracle databank system for recording of processing parameters

- integration of all automatical and manual production steps

- optimised sand drying

- energy management

StaKo Tec. service package:

- base study

- implementation, extension and software adjustment on site

- training

- remote maintenance