Closed projects food industry

Closed projects out of the scope of food industry.

References in food industry

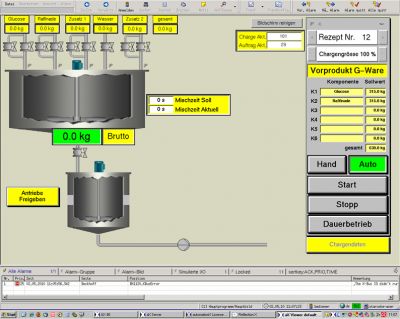

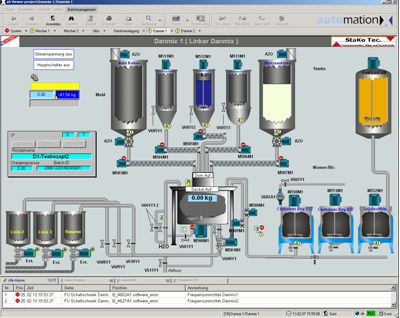

Control and visualisation of a mixing device for liquid sugar

Place of delivery: Germany

Technical data:

- mixing device for the production of liquid sugar

- batch management integrated in AutomationX

- recording of the batches in a MySQL databank

- data memory on a network disc with Raid 1

- Beckhoff Ethernet E/A system

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- implementation

- training

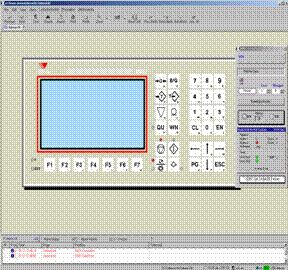

Software for Pfister weighing terminal type MSR 3

Place of delivery: Canada

Technical data:

- preparation of a software for the recording of batch parameters of a Pfister weighing terminal type MSR 3 and for data memory in an Access databank

- supply of the facility to Canada

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording and evaluation with Access databank on customer's demand

- training

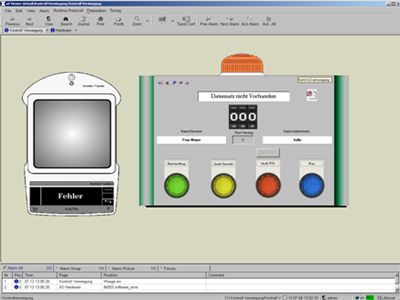

Control weighing of the finished packaging of wafer pastries

Place of delivery: Germany

Technical data:

- control weighing of finished packaging for wafer pastries

- approx. 300 raw materials and ready packaging

- Access databank and frontend for data evaluation

StaKo Tec. service package:

- preparation of data link with a calibrated Mettler-Toledo scale

- construction of robust operator boxes with VIPA in and outputs

- generation of Access databank and software for statistical analysis of the weighing data with Access databank

- evaluation of data of the quality control operator places

- electric engineering

- implementation

- training

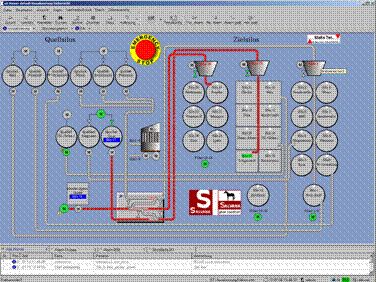

Control and visualisation of a pet food device

Place of delivery: Germany

Technical data:

- silo loading with diverse selectable conveying lines

- approx. 250 physical in and outputs

- control of multiple production plants

- management of approx. 50 raw materials

- integration and recording of all automatic and manual production steps

- vehicle control with network cameras

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- data recording and evaluation

- electric engineering

- construction of swith cabinet

- implementation

- training

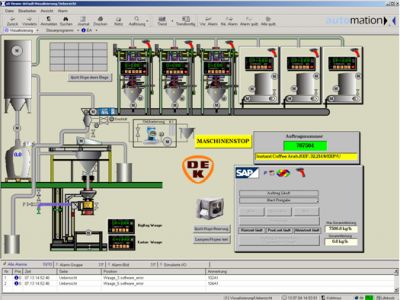

Control and visualisation of a calibratable blending line for the production of instant coffee

Place of delivery: Germany

Technical data:

- calibratable blending line for the production of instant coffee

- 450 physical in and outputs

- differential dosing, conveying road and burdening weighing system

- online raw material control system with SAP

- recording of all automatic and manual production steps

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation

- real time data link to SAP (RFC)

- elektric engineering

- construction of switch cabinet

- implementation

- training

- 24h support 365 days per year

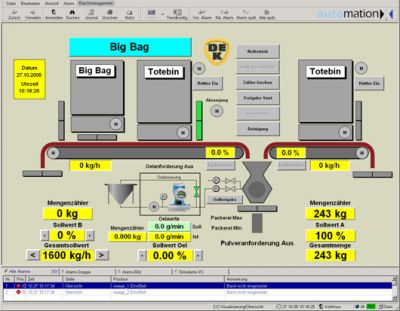

Control and visualisation of a blending line for the production of instant coffee

Place of delivery: Germany

Technical data:

- 4 blending lines for the production of instant coffee

- 150 physical in and outputs for each line

- conveyor road weighing system

- continuous oil dosing system in the scope of mg

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of steering and visualisation

- electric engineering

- construction / reconstruction of switch cabinets

- implementation

- training

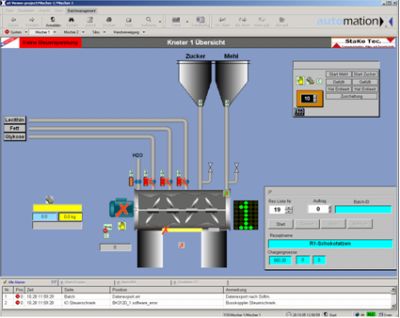

Control and visualisation of a mixing device for the pastry production

Place of delivery: Germany

Technical data:

- 2 mixing devices (kneaders) for pastry production

- Access databank for proccessing data analysis and data transfer to SOFT-M

- connection AZO steering system

- multiple control clients

- data recording of manual control panels

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisation, S88-2 batch system

- electric engineering

- construction of switch cabinet

- implementation

- training

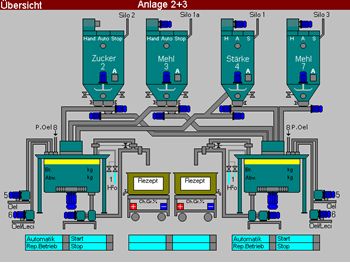

Control and visualisation of a mixing device for the production of wafer pastries

Place of delivery: Germany

Technical data:

- 7 mixing devices for the production of wafer pastries

- Dos batch managment with Pfister MSR systems

- connection automationX to batch managment system for viscosity control and trend recording

- data link 4 S7 control via MPI/Profibus

- data export to MySQL databank system

- Beckhoff Ethernet E/A system

StaKo Tec. service package:

- base study, reengineering control technology

- preparation of control and visualisisation

- Dos batch managment

- electric engineering

- construction of switch cabinet

- implementation

- training

Extension of an automationX control system of a batter mixing device

Place of delivery: Germany

Technical data:

- 2 batter mixing devices for the production of wafer batter

- MySQL data bank

- WEB frontend

- data bank evaluation

- integration of AZO control system

- multipe control clients

- data recording of manual control panels

StaKo Tec. service package:

- base study, reengineering control technology

- extension of the existing automationX control

- S88-2 batch system

- electric engineering

- construction of a switch cabinet

- implementation

- training

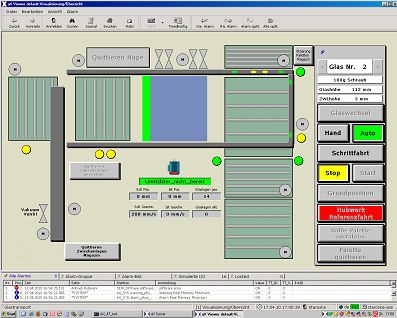

Control and visualisation of a jar depalletising facility

Place of delivery: Germany

Technical data:

- jar depalletiser for the transfer of empty jars towards the filling process

- 150 physical in and outputs

- 6 frequence converters

- one positioning drive

StaKo Tec. service package:

- base study, re-engineering control technology

- preparation of control and visualisation

- electric engineering

- optimisation of capacity

- construction of switch cabinet

- integration of a SEW positioning drive

- implementation

- training

- remote maintenance